As fishing season heats up, tournament anglers all across the country are beginning to prep their tackle and gear — boating equipment included. And no matter what level they compete at, getting to the fish fast will be a high priority.

To realize optimal top-end hull performance, matching your outboard with the correct prop is essential. And that boils down to having the right model and pitch not only for top-end speed, but for overall performance and fuel economy, as well.

Although most bass boat manufacturers dedicate many hours of testing to determine the best all around prop for their various hull-outboard combinations, there are other variables that can impact performance. How a boat is rigged and loaded — even altitude and climate — will make a difference.

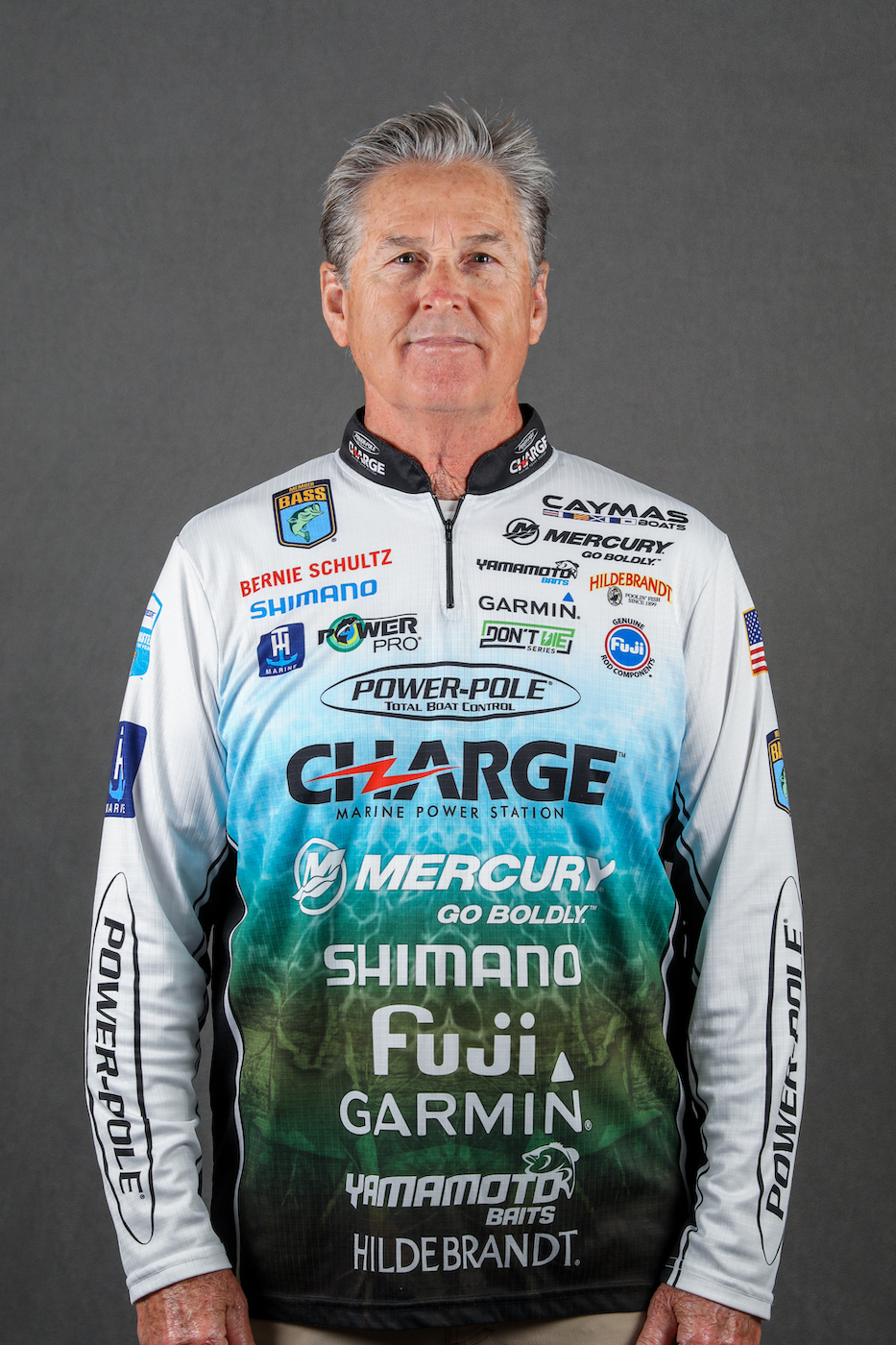

I run a Ranger Z-520c powered by a Mercury Optimax 250 Pro-XS, and the prop I use is a 26-inch pitch Quicksilver Tempest Plus. That’s basically how it was set up by the factory.

The performance rigging department at Ranger spends countless hours testing their various hulls with different make and size outboards to determine the best all around performing props. Note that I said the “best all-around” performing props. Depending on your personal preferences or boat’s specific setup, other options are available.

A Higher Source

Scottie Beattie of Mercury Marine’s Technical Support Team knows how to make outboard engines perform to their fullest potential. According to Beattie, realizing maximum top-end speed in a tournament-rigged boat requires good hull lift. Because of the way bass boats are designed, weight distribution becomes a major concern.

He tells me that I’m like most anglers. I have a tendency to put too much tackle and gear onboard, especially towards the bow. And he claims that defeats bow lift, even with the perfect prop. As he puts it, “A prop can only do so much.”

Beattie suggests trimming some of the fat while redistributing as much of the load as possible towards the rear of the boat. By eliminating excessive weight at the bow, the prop can then turn faster — which should lift the bow and result in a higher top-end speed. The key is to achieve this without compromising hole shot.

After that, he says all around performance is further tweaked through these three important variables — RPM, speed and fuel flow. Only the right propeller for any specific hull will help to achieve these in proper balance.

The Optimax 250 Pro-XS engine I run is designed to peak at around 5800 RPMs, and anything lower or higher, according to Beattie, can put the engine at risk. If yours is turning a higher number, he recommends going up one size in prop pitch. And if it’s turning a lower number, he says go down a size. If either these fail to remedy the problem, then you may need to try another style prop altogether. (This RPM guideline is solely intended for Mercury Optimax 250 Pro-XS engines. For other sizes or brands, consult your owner’s manual or a licensed, certified dealer).

Once the proper RPMs are realized — along with good hull lift — you should begin to see improved top end speed. Then it’s a matter of fuel flow (or fuel consumption), and only a mechanic’s ECM tester or Mercury’s SmartCraft gauge can tell you if you’re burning the right number of gallons per hour.

Beattie emphasizes that having a giant rooster tail shooting from the prop doesn’t necessarily equate to fully realized top-end speed either. To the contrary, he says it could actually indicate a loss of potential thrust, and that the prop is actually “blowing out” to some degree.

Again, in his estimation, good all around performance comes with a balance of proper RPMs, realized top-end speed and leaner fuel consumption.

Climate Change & Other Concerns

Another factor to consider is climate or, more specifically, air density. Under hot summer conditions, when air is thick with humidity, outboard engines work harder. During the dry season, they function smoother. Beattie claims going up or down one size in prop pitch can help to compensate for these swings in barometric pressure.

This is especially true in certain parts of the country where climate patterns are extreme, such as the arid southwest or humid southeast — or at higher altitudes where the air is thinner.

For denser air, he suggests dropping down a size, so the prop can turn more easily. Conversely, he says go up a size in thinner air. If these fail, he suggests changing to a different prop style altogether, such as a four or five-blade version — something that can also pay off when operating a vessel under extreme rough water conditions. Beattie says, “More blades equal better bite.”

Something else to consider is prop wear, and not all wear is obvious. In fact, substantial performance loss can result from unnoticeable edge or cup wear. Beattie claims grinding a prop through shallow water sand, or even coarse mud, can remove some of the cup and cause significant edge wear that you might not be able to see. The result is reduced bite, which translates to less thrust, resulting in less bow lift. And remember, less lift means less top-end speed!

Something else to watch out for is fishing line — especially braid! According to Beattie, nothing will wear out a seal or scar a prop shaft quicker than braided fishing line. To prevent this from happening, he recommends removing the prop periodically for a quick checkup. And while you’re at it, he suggests checking the plastic hub assembly. This part is made of plastic for a reason — to fail on impact, so that the prop shaft or gear case may be spared any potential damage. Look for abnormal wear, like grooving or cracking. If you see any, replace the hub immediately.

Performance Summary

Something I noticed long ago was the tendency for many tournament anglers to run Mercury Quicksilver props on their engines, no matter what the brand. According to Beattie, it’s a common practice. He says the reason is simple: Mercury builds the best performance props in the industry.

So no matter what hull and outboard combination you run, try experimenting with various styles and sized props…especially if your boat is rigged with an offset jack-plate. You might realize a significant increase in top-end speed, while saving a few bucks in fuel costs.