As the 2013 Bassmaster Elite Series approaches, all of the competitors are busy completing their last-minute preparations. And along with those duties is the business of wrapping our boats.

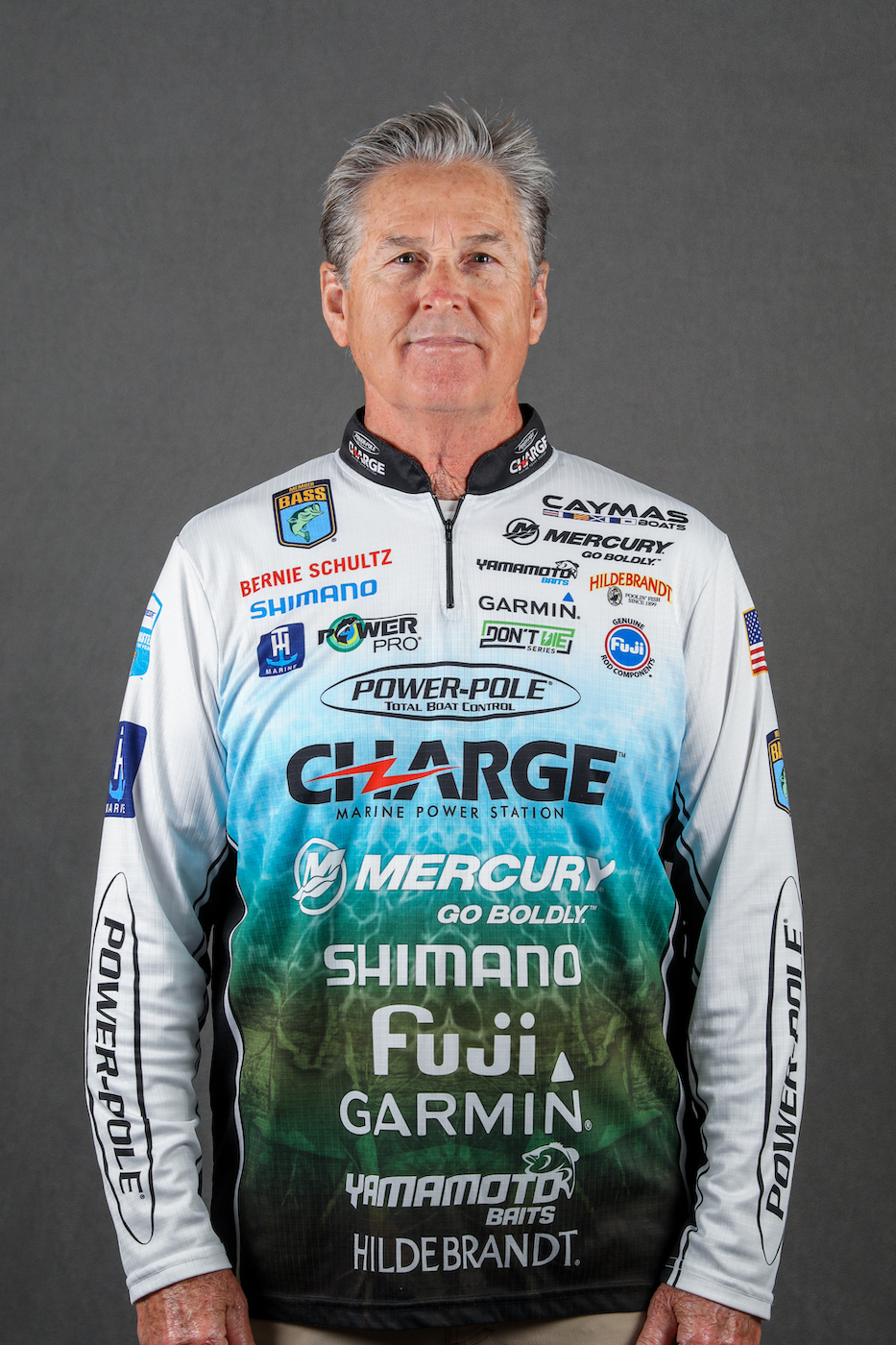

Colorful and creative, boat wraps are meant to add impact for sponsors — and that they do! Each is unique, and to some degree, a statement about the competitor. You could say they’re as distinctive as the personalities showing them off.

But before the Elite Series began, boat wraps were rarely seen on competitor boats. Tournament organizations used them to tout tour sponsors, but few anglers had any use for them … or so they thought!

Then came the Elites, and B.A.S.S. officials decided it would be a great way for the anglers to brand themselves while promoting their sponsors. So templates and guidelines were established, and every pro was required to develop his own “look,” so to speak. And there’s no doubt the concept has added impact to the tour.

Getting Started

Most anglers seek what’s known as a “title sponsor” — a dominant brand to carry the overall design of their wrap. Of course, more space means more money, and that’s something savvy companies are willing to pay for — so long as it’s within their budget. In some cases, anglers will work with more than one title sponsor, figuring out a way to split the costs and space equitably. Either way, it’s all about branding and the placement of logos so that supporting sponsors see some real benefit to a floating billboard.

Once the title sponsor is secured, anglers then work with that sponsor to create an attractive motif, usually involving an ad agency or sign company for graphic support. The graphics are created on a computer by someone with the talent to blend and layer images together. It’s neat to watch, as they move the separate components of the design around until they fit ideally against the 2-dimensional template of a boat. This is all done to scale, obviously, so experience really pays off when adapting the image to the real thing.

Once a design is agreed on, the draft is then submitted to B.A.S.S. tournament officials for approval. Just like NASCAR, B.A.S.S. requires all designs to fall within their creative guidelines — so that there is some consistency, or harmony, among all of the boats. Tour emblems are assigned to certain places with the free space left for sponsor signage. Once approved, the wrap process begins.

While there are countless sign companies out there, not many are proficient with wrap installation — particularly on boats. When you’re dealing with a 3-dimensional shape that’s exposed to the elements and rough treatment, the wrap has to be applied accordingly. And believe me, Elite Series pros put their boat wraps to the test!

I work with Wrap This Ink, a division of Media-1 in Orlando, Florida. They do wraps for B.A.S.S., Bass Pro Shops, the Toyota Team and countless other hi-profile brands. The guys there all fish, so they take great pride in their work and the fact that it’s seen by so many fishing fans.

The in-house graphic artists at Wrap This Ink work out the details of the design on a computer, making sure everything is right. Once the final touches are made, printing begins.

Sign companies use large printers that handle 4-foot roles of adhesive vinyl film (3M is preferred). The film feeds through the printer similarly to those used in a home or office, and these larger versions use ink jet systems much like their smaller cousins. When the printing is complete, the ink is allowed to cure for 24 hours. After that, it’s time for installation.

Getting It Right

Before the film can be applied, technicians begin the stripping process — which means they temporarily remove anything that could prevent a quality installation, such as rub rails, cleats, boat company decals, etc. Installers want a smooth, unobstructed surface to work with — sort of like a fresh, new canvas for a painter.

Once stripped, the gel coat is wiped clean with alcohol to remove dust and other impurities. With a perfectly clean surface to work with, installers begin at the rail, positioning the material so that the images line up according to the computer draft. Here’s where talent and experience comes in—mess this first step up and the entire wrap could be wasted.

Slowly, using hand-sized squeegees and a heat gun, the installers spread the wrap against the boat’s surface — working outwardly from the center — slowly molding the material to the contour of the boat. When trimming is required, installers use a string-cut method to avoid slicing into the fiberglass surface beneath. This is tedious work, but important to the boat’s finish when the wrap is eventually removed.

Once the wrap is fitted and trimmed, then “second surface” application begins. This simply means the addition and placement of smaller decals. It’s also when the rub rail, cleats and any other removed components of the boat are reinstalled.

With the wrap complete, the sign company then takes digital images to file for future reference. All in all, it’s about a two- to three-day process when done right, and the total cost is around $3,000. That may sound expensive, but when you consider the number of impressions these floating billboards receive, it’s actually quite reasonable. And besides, when the customer comes to see the final product, it’s a proud time for all involved. A freshly wrapped boat is a beautiful thing!

So when the Elites roll out this season, be sure to identify with your favorite angler by becoming familiar with his boat wrap. He — and his sponsors — will appreciate it.