When it comes to high-stakes fishing, professional anglers will do almost anything to get to the fish — even if it means abusing their equipment.

They won’t think twice about grinding bottom to access a skinny backwater or braving massive, open-water swells to reach a distant hot spot. Some will even jump beaver dams, or scrape their Power-Poles and engine cowlings while trying to pass through culverts or beneath low-lying bridges.

It’s all about getting to places others rarely consider.

Sometimes it pays. Other times it doesn’t. Either way, you can bet some will always try in order to separate themselves from the field and to increase their odds of success.

Backwater water daredevils

Among the more daring is Florida pro, John Cox. John utilizes his aluminum, Mercury-powered Crestliner like an all-terrain vehicle, maneuvering it into places where heavier glass boats can’t go. Looking back on his record, it’s a tactic that’s paid off repeatedly.

Former Elite, Keith Poche is another backwater daredevil. I’m sure many of you have watched his videos, jumping logs, and sandbars to access hidden creeks and ponds … extreme shallow water boat handling that’s not for the faint of heart.

There are other types of risk-takers. Guys like the Johnston brothers, famous for battling huge waves and gale-force winds on the Great Lakes. Fellow Shimano pro, Cooper Gallant is another who braves big water. It seems Canadians are just built for it.

There are others, too. In fact, most of the Bassmaster Elite Series field will gamble with their equipment, especially if they believe it will lead to a better payday and some extra AOY points. It’s part of the game, and at times it can be costly. All sorts of equipment failures can result.

Mechanical mayhem

Even when we’re not taking risks, things sometimes break or malfunction for inexplicable reasons. Poor rigging, too, can cause problems.

My season was bookended with mechanical issues. Whether it was due to faulty rigging or equipment failures, I spent an inordinate amount of time getting things fixed. And too many times it occurred during competition hours.

I’m not making excuses, and I’m by no means the exception. Truth is, most of the field will experience mechanical problems at some point during the season. When it happens in competition, it’s the worst. But even when it occurs during practice, that can be costly too … as that’s valuable time lost when we should be looking for fish.

Most Elites are good about maintenance. In fact, many are meticulous about it. Even so, things sometimes wear out, especially when you’re dealing with adverse conditions. Although most of our equipment is built to endure even the harshest treatment, when things break, it’s nice to know we have backup.

The service yard

At each Elite Series event, representatives from all the major boat and outboard companies come together to form what’s referred to as “The Service Yard.”

Companies like Mercury, Yamaha, Caymas, Skeeter and Bass Cat send factory technicians with large trailers to set up mobile repair shops, complete with the necessary tools and replacement parts required to keep us on the water. With them are techs from various marine accessory companies, including T-H Marine and Power-Pole. Even electronics companies are present. And though these guys may represent competing brands, they’re like a big family — a brotherhood of mechanics, so to speak.

Like us, they live on the road, traveling from town to town, venue to venue. They stay at the same hotels, eat at the same restaurants, and are there for us whenever we need them.

The service yard is usually located at the main boat ramp where our takeoff and weigh-in ceremonies are held. The crews arrange their trucks and trailers much like the pits at a NASCAR event. When one has a big job to do, the techs from other companies often chip in. They swap tools and know-how in order to get the job done quickly and correctly. It’s amazing to see how efficiently they work, especially when pressed for time.

Another part of their responsibilities is monitoring our equipment. Oftentimes we’re testing prototypes or newer products and they need feedback on how it’s performing, particularly under adverse or extreme conditions. And as any service tech can tell you, tournament fishing dishes out plenty of that.

Although the average angler would never put his equipment through what we will, he or she still realizes a benefit in the long run — as it’s our field testing that makes the end product more reliable and durable.

So the next time you’re watching your favorite pro battling the competition, keep in mind that he’s not entirely on his own — there’s a complete team of factory technicians behind him, making sure he can compete at the top of his game.

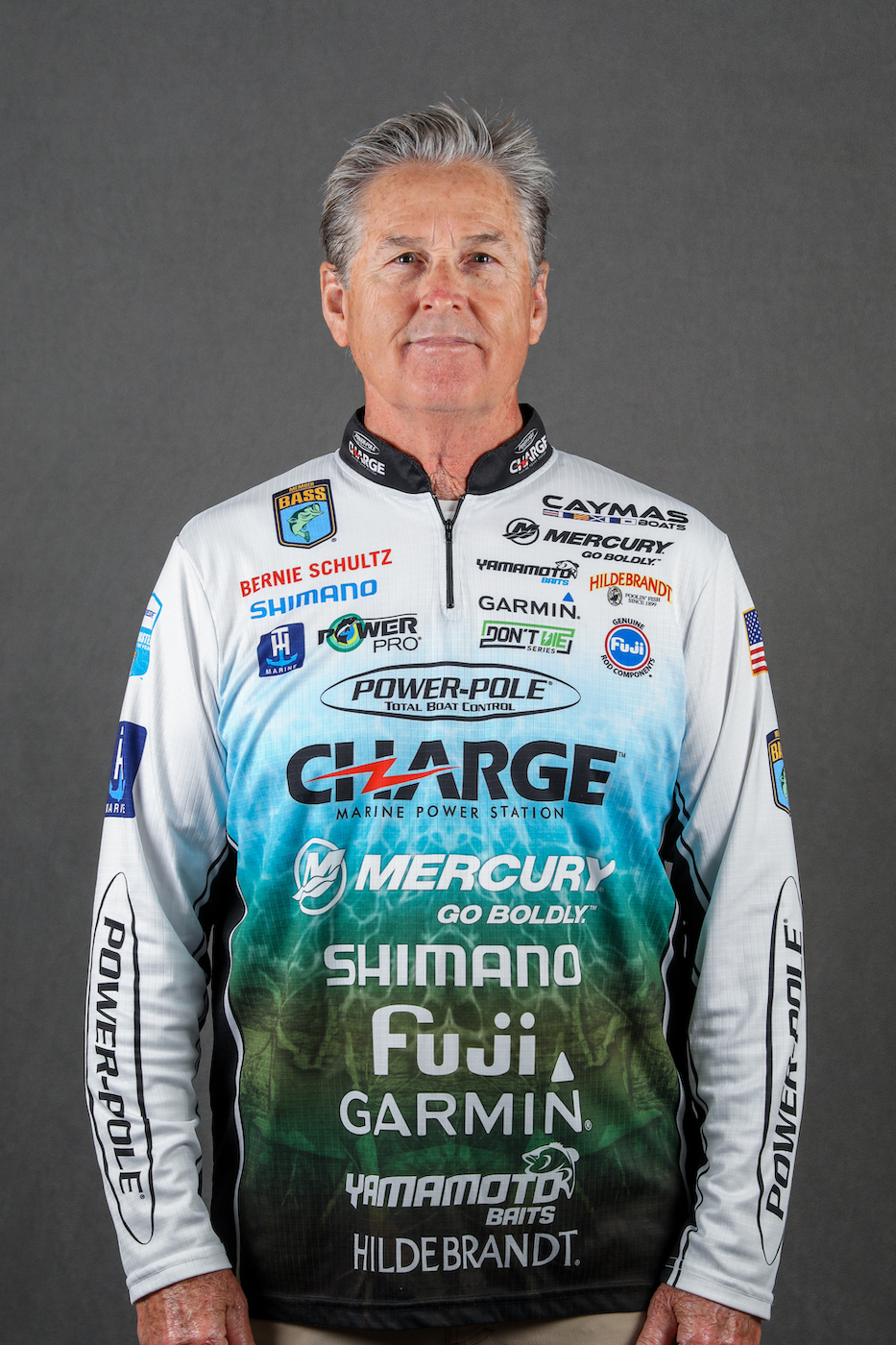

Follow Bernie Schultz on Instagram, Facebook and through his website.