Each year, pro anglers make a move to newer boats, but not always because we choose to. It’s more because we’re expected to.

Our sponsors want us showcasing their latest products. That includes boat companies, outboard companies, electronics companies … you name it.

Of course, like you, we love new boats. But when you factor in the short amount of time in which we have to order, rig and prep our boats, transitioning from one to another can become a race against the clock.

There is so much involved. Tweaking everything so that it functions as desired involves considerable time, effort and expense. And once you get a boat completely dialed in, it’s not something you want to give up. At least not me.

Nevertheless, new boats are a must and we all try to stay with the pace.

That said, here’s a closer look at the process.

Out with the old

At the end of the season, the first order of business is to strip the current boat of its vinyl wrap and deck graphics. And that’s a big job.

Like a huge, form-fitting decal, the vinyl is adhered securely to the boat’s surface with strong adhesives. Removing it takes time, especially with any extra reinforcing adhesive applied to corners, curves and other stress points. To get it all, special solvents are used. But before that happens, the windshield, cleats, light fixtures and all other trim pieces have to be removed from the boat and trailer.

Then come the deck graphics, which are a much heavier, tread-like material. Once those are off, a serious power washing or steam cleaning is required.

If two people work at it steadily, the job usually takes a full day … sometimes more. Once everything is back together and looking good, then the boat can be delivered to its new owner — assuming there’s a buyer on hand.

Many anglers presell their tournament rigs before the tour ends. Others look for buyers through the Internet or by word of mouth afterward.

In the meantime

While the refurbishing process is going on, most touring pros are busy ordering all the equipment needed for their next boat. And that process can differ from one manufacturer to another — even one angler to another, depending on their level of sponsorship with those brands.

I run a Ranger, and I have for more than 30 years. In that time, I’ve grown accustomed to their process. And, yes, there’s a lot of paperwork involved. We’re required to file an application for renewal, regardless of how long we’ve been with the company. The same goes for my outboard manufacturer, Mercury Marine.

To be approved, you must first have a dealer and regional rep sign off on the application. Once that’s done and the pro staff managers approve everything, you can submit an order, which is subsequently filed and returned for confirmation.

After that, you’re in line for production — which can take up to 3 months, maybe more.

In with the new

When the new boat arrives, it may or may not be fully rigged. Some boat manufacturers offer complete rigging services. Others do not. And in some cases, touring pros prefer to do their own rigging … at least some of it.

Ranger does most of mine, and what they don’t do, I have my dealer or other sponsors finish. They hang the engine and hydraulic jackplate, and mount all the electronics. Because I’m sponsored by JL Marine (makers of Power-Pole Shallow Water Anchors), I have them install the poles at their factory in Tampa, Florida.

After that, I bring the boat home to my local trim shop, to have the boat cover custom fitted for long-distance hauling. Then it’s off to Media-1 for the new wrap graphics.

I’ve worked with Media-1 since the inception of the Elite Series back in 2006. They do all my wraps at their facility in Orlando, Florida. In fact, they do wraps for a multitude of the other pros on all the major tours.

The wrap process is usually pretty quick. First, I’ll work with their top designer, Jason Wissig, on the overall layout. Once we agree on the final mockup, he prints it onto vinyl using massive Hewlett-Packard printers.

Meanwhile, their installation crew is prepping my boat for the wrap’s application. Essentially, they de-rig the boat — which involves removing the trolling motor, rub rail, windshield, trailer fenders and any other components that might interfere with the application process.

Once the wrap is printed and cured overnight, it can be applied. That involves hours of tedious work. When the first surface is fully installed, the boat and trailer components are reattached so that the second surface can be applied. That includes any smaller decals inside and out. After that, the deck graphics are applied.

My wrap and overall “look” will be very different for 2019. I have a new title sponsor and that company’s colors call for a different palette. It’s bold, too, and I think you’ll like it when you see it.

On the water

After everything is completed, then it’s time to splash the boat and break in the motor. This usually takes a day or two, depending on how much time you’re willing to devote to running the engine at low, varying RPMs.

It’s also a good time to get acquainted with the electronics. Like all computer equipment, GPS/sonar technology is constantly advancing. So, unless you’re running the same units as before, there’s a lengthy tutorial process involved.

And that pretty much sums it up.

So, by the time you’ve read this, nearly all of the Elite Series pros will have logged months of preparation — not just on their boats or tow vehicles, but all aspects of their equipment. And for most of us, the opener on the St. Johns River will be the first opportunity to put that equipment to the test.

I’m looking forward to it.

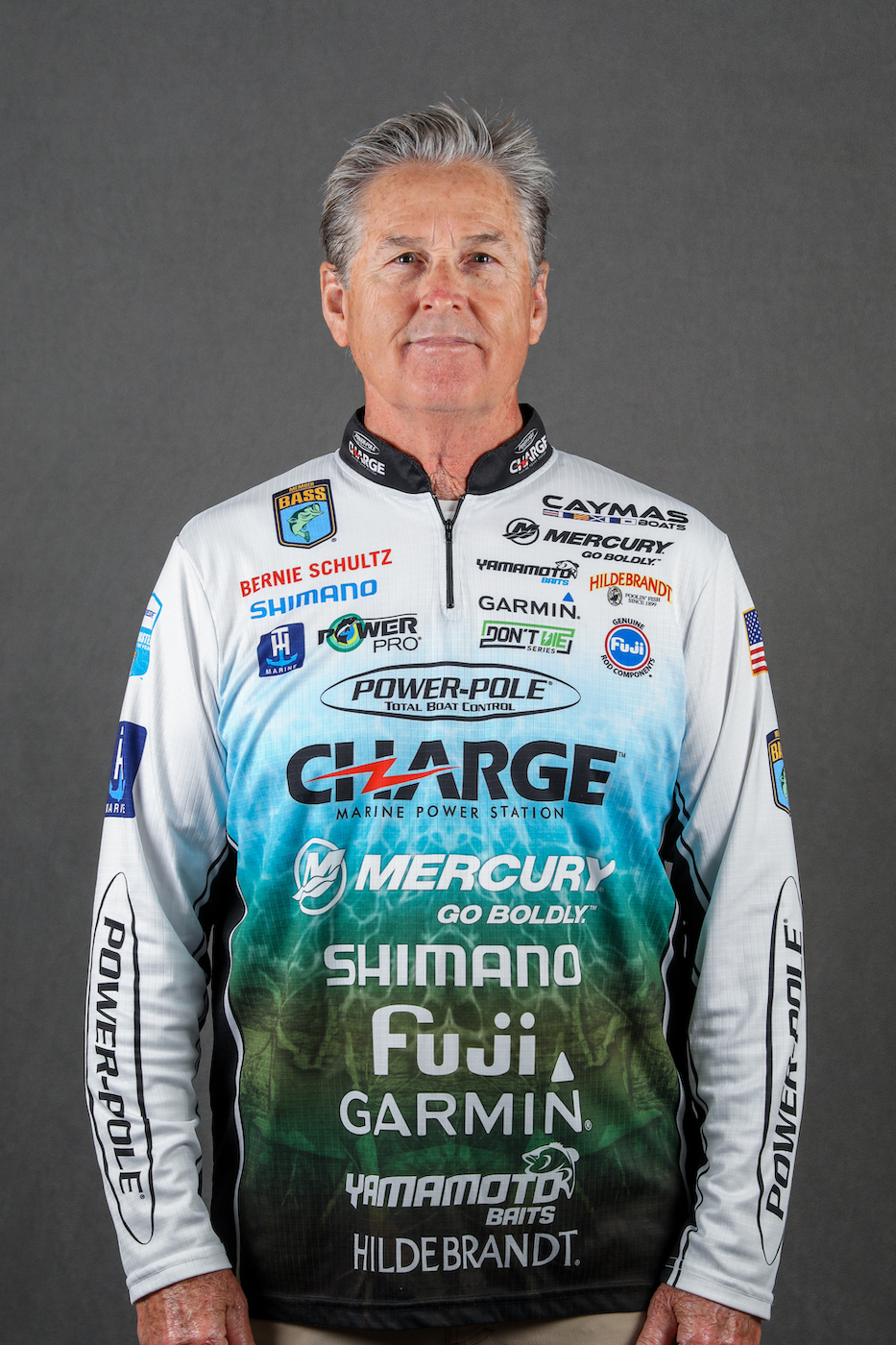

Follow Bernie Schultz on Facebook or through his website.